Daecon Trusses Process

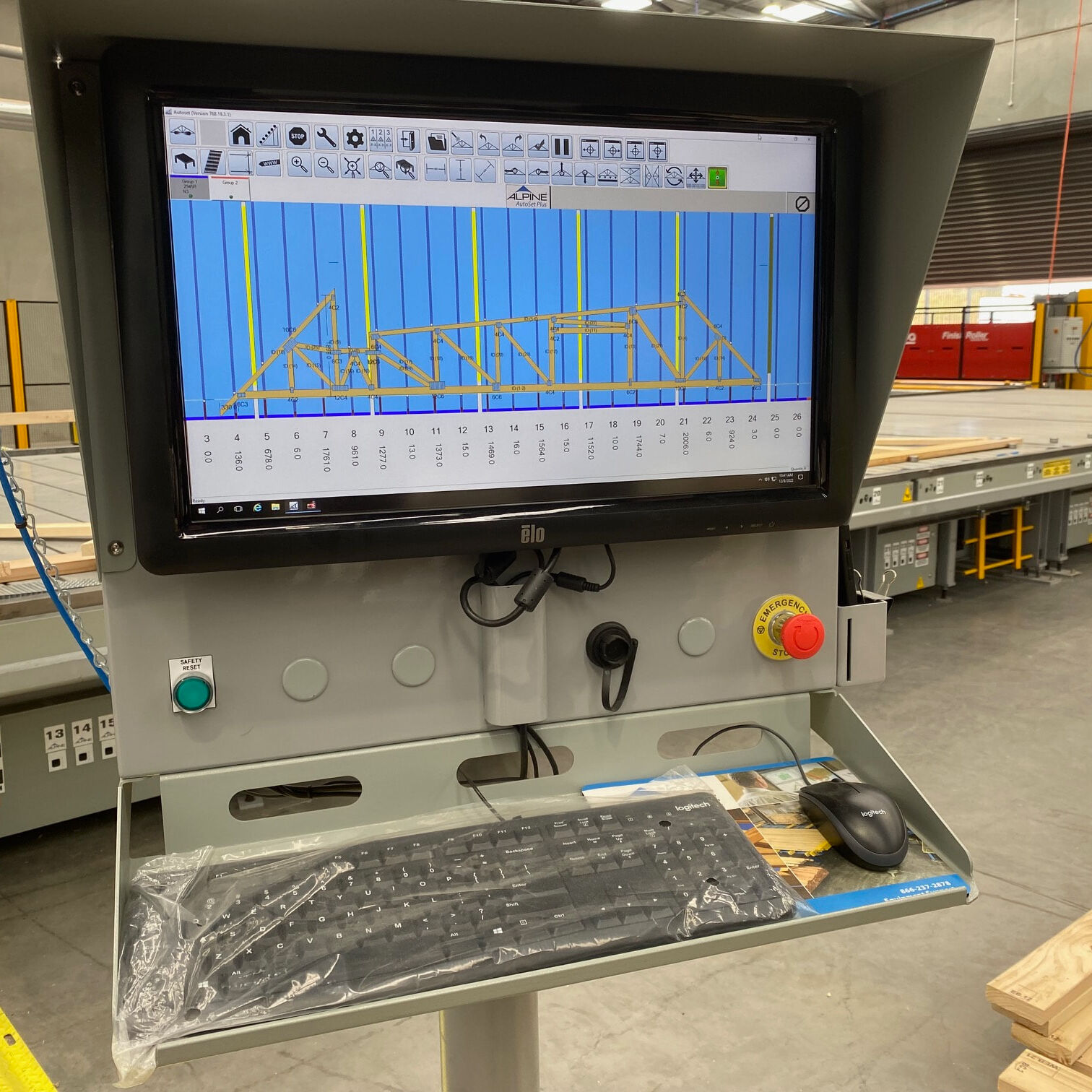

Our State of the art factory is equipped with the latest in technology providing a level of accuracy for customers that is unmatched by our competitors. Our internal technical skills and the latest equipment combined help produce the highest quality finished product.